What To Look For When Buying A Serger:

You know, if you buy a cheap serger from a box store, you will be very frustrated. So don't! What is the difference? "Tolerance."

When a machine is manufactured, the manufacturer sets a tolerance level. "Low tolerance," means they don't tolerate any sloppiness in the manufacturing process. A "low tolerance" factory will make a quality machine. The metal has to meet a certain quality. The parts have to fit together tightly, without any "play." You can detect a serger that's made in a "high tolerance" factory (where they allow sloppiness), by grabbing the needle bar and see if it will wiggle forward and backward. If it wiggles forward and backward, we can't set the needle/looper distance (a timing setting), because it's variable. If the metal is cheap, the screws strip, and the parts wear out quickly. It then becomes a disposable machine. When you take a cheap machine in for a repair, we don't have much to work with. Sometimes we will tell you it isn't worth the cost of having it repaired, because we CAN fix it, but it won't STAY fixed.

Three features that you really want on a serger are 1) a built-in rolled hem, 2) differential feed, and 3) a tall thread rack.

#1 The rolled hem is such a great way to finish a raw edge. You can use it to finish the edge of a ruffle, instead of folding it in half. You can finish table linens or anything else that you don't want to put a hem on. On most machines, there's a switch in the front that's pushed forward for regular serging, and pulls back for a rolled hem.

#2 Differential feed means that you have 2 feed dogs. The back feed dog goes the same speed all the time. The front feed dog can be adjusted to go faster or slower. So, if you're sewing on a stretchy fabric, and you don't want it to stretch out and be wavy, you can speed up that front feed dog. However, if you do want it to stretch out and make a "lettuce leaf edge," you can make the front feed dog go slower. Also, if you're sewing with a non-stretchy fabric, and you want to gather it up a bit, you can speed up the front feed dog, and it will gather it. You'd need a gathering foot to get deep gathers, though.

#3 A tall thread rack may seem like a little thing, but the taller the thread rack, the nicer the thread feeds off of the spool. And it is sooooo important for the thread to feed well off of the spools. If it doesn't feed well, where the threads are supposed to lock on the edge, will wave.

I'd like to show you a few things about serger repair.

Here's a common problem we see with sergers. There are 2 pins in the needle plate that hold the fabric stable as the stitch is formed. Sometimes they get bent or broken off. Sometimes you can bend the bent pin back in place. The pin on the left is too bent, and will have to be replaced. The pin on the right is broken off, and will also have to be replaced. Some sewing machine mechanics are willing to replace these pins, others will just have you buy a whole new needle plate.

__________________________________

I worked on this serger a couple days ago. The woman says she sews on flannel every day. If you'll look closely at the needle plate, you can see that the center support is broken out and pokes up in the front. And the support between the pins is broken and pushed down. The cause of the break is the amount of lint that's packed into the feed dogs. WOW! That's a lot of lint!

|

| You can click on the image to get a closer look. |

Moral of the story... it's a great idea to remove the needle plate, and clean out the lint every once in a while.

_________________________________

|

| In this picture, the thread puller is knocked out of position. |

|

| Here, I've loosened the black screw, and moved the arm so it's even with the looper arm behind it, then re-tightened the screw. |

_____________________________________________________

When sergers sit unused for a long time, the old oil will turn into a gummy mess. So, if you can't turn the handwheel, that usually means you have a gummy mess inside. Then we have to remove the old oil with a "solvent," remove the solvent and whatever it disolved, then re-oil.

To prevent this from happening to your serger, just get it out and use it every month.

_____________________________________________________

This poor serger! Its owner should be reported to the sewing machine abuse council!

Strike 1: Bad thread.

Strike 2: The thread rack is on backwards -- the thread needs to pull straight up off of the cone.

Strike 3: The far left spool pin is broken off.

Strike 4: The pad under the spool pin is falling apart.

Strike 5: The thread puller is out of position.

This is a great serger! We'll just clean it up and it will run like new.

After its been cleaned and oiled, we'll put the thread puller back in place.

Then we need to repair the spool pin. I cut a spool pin off of another machine that was in the "bone yard."

I used a Dremmel to make a hole through the bottom of the base. Then I used the Dremmel to hollow out the spool pin.

Select a screw that will stick up about 1/2" past where the old spool pin broke off. Make sure the screw and hollow spool pin with fit together nicely.

Mix up some 5 minute epoxy, and put it inside the hollow spool pin. Screw the new spool pin on, and let it sit until hardened. Clean up any excess glue.

Not a very good picture, but you can see the position of the thread rack. It even has a sticker on it that tells which side should go towards the front.

Didn't have time to take more pictures, but it sewed-off beautifully!

_______________________________

Skipping Stitches and Tension

(A reply to Anne B. that may be helpful to someone else.)

The first thing we need to check when a machine is skipping

stitches, is the needles. Have you put

new needles in? And are they pushed all

the way up? When pushed all the way up,

the needle on the right will be a little longer than the needle on the

left. Some Singer sergers take a very

specific needle. Go wherever Singer

needles are sold, then look for the serger needles. They’re different from other brands because

the top of the shank is very small. Use

a size 75 to 90 needle.

The next thing to check is the needle guard. This is under the needle plate and is like a

shield on both sides of the needle (front and back). Do the needles hit the needle guard? That’s something you can adjust.

Then make sure there are no burrs or damaged needle plate pins.

If you’ve checked all of this, and you’re still skipping

stitches, it’s time to take it to the shop to have the timing adjusted. That’s something you probably don’t want to try

yourself.

It sounds like the Juki’s timing is waaay out, or it has the

wrong needles in it. The older Juki’s also

take a very specific needle, the BLx1. The

newer Juki’s take a regular Schmetz or Bernina 130 705H. Use a size 75 to 90 needle.

The timing settings on a serger are quite complicated. #1. The needle bar has to be the right height in relation to the feed dogs. #2. The lower looper has to take the thread off the back of the needles, and hit just above the needle eyes. #3. The upper looper has to pass in front of the needles,and move far enough to the left, to allow the needles to catch the loop of thread. #4. The loopers have to be very close, but not touch, and the lower looper has to cross behind the upper looper, just under the bump. #5. Both loopers need to come very close to the needles, but not touch. #6. The cutting arm needs to be in sync with the feed dogs.

As for the tensions, you’ve got to start with a good thread. A couple that we’ve had trouble with are

Mediera and Guterman. There’s also some

that comes on a very big cone, and is very stiff (don’t know the brand). If you use Maxilock, you’ll always get your

best stitch. Then make sure the thread

is pulling straight up, off of the cone.

The easier it comes off of the cone, the better your stitch will

be.

Turn the tension dials to zero, then blow them out with an

air compressor or canned air. Then put

them all on 3, and start adjusting them by how your stitch looks.

Start with the needle tensions. They are the straight lines on the back of

the fabric. If they’re looping, tighten

the tension. If they’re pulling too

tight, loosen them.

Then work with your loopers. You want the ridge, where the stitches lock together, to be balanced on the edge of the fabric. If the ridge is coming tightly to the front,

loosen the front. If it’s coming loosely

to the front, tighten the back. If it’s

coming tightly to the back, loosen the back.

If it’s coming loosely to the front, tighten the back.

I hope there’s something here you can use.

---------------------------------------------------------------------------------

---------------------------------------------------------------------------------

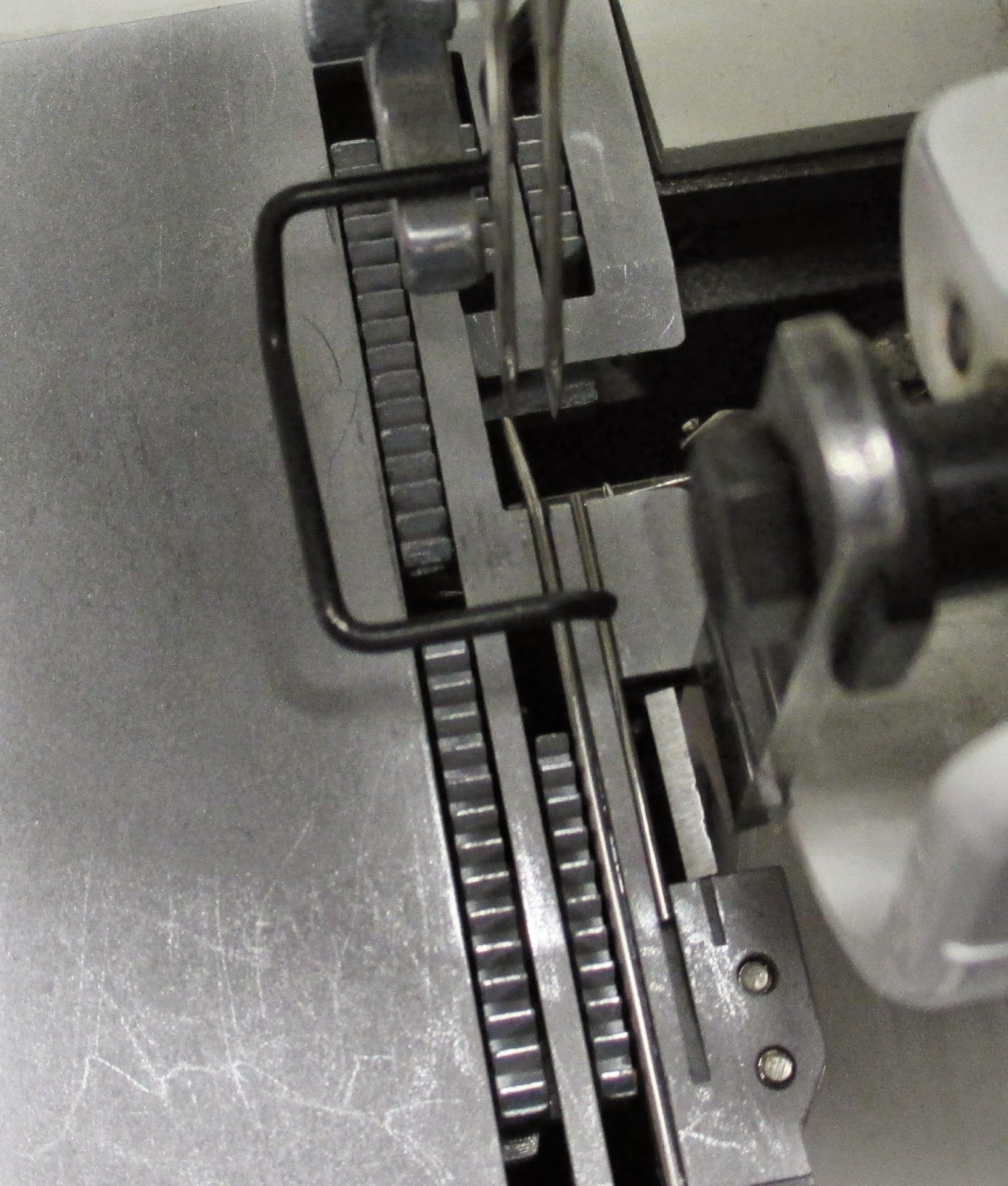

Here's some pictures in reply to serger timing.

There’s a bolt/screw at the bottom of the lower looper that holds it onto the shaft. If you loosen it, you can move the whole arm.

|

The

lower looper should pass behind the needles and the tip should be just above

the eye of the needles.

|

| |||

| The loopers should only have a tiny space between them, but they should “nest” together. |

----------------------------------------------------------------------------------

Here's a schematic of a Bernina 800D serger feed system. If your differential feed isn't working very well. Try some Tri-flow Superior Lubricant or WD-40 to get things loosened up. Focus on the area under the left side of the serger.

The rolled hem is such a great way to finish a raw edge. You can use it to finish the edge of a ruffle, instead of folding it in half. You can finish table linens or anything else that you don't want to put a hem on. embroidery machine reviews

ReplyDeleteI have an Elna dcpro5 serger. I love the machine. Yesterday I discover 2 spool pins were broken. how can I fix them?

ReplyDeleteWhy is my differential feed stuck? It won't move I can serge overlock but no gathering or anything that requires a cxhange in the differential feed.

ReplyDeleteI have a simplicity easy lock 850. Purchased used. The feeder dogs do not seem to move? Any suggestions? Rrgw45@gmail.com

ReplyDeleteI have a simplicity easy lock 850. Purchased used. The feeder dogs do not seem to move? Any suggestions? Rrgw45@gmail.com

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteMy first guess would be that the feed dogs are packed with lint. So you’d need to remove the needle plate and clean any lint in the feed dog area. My second guess would be to check the stitch length, which would be inside the left side cover. Loosen the screw and slide the indicator to about 2 1/2. My third guess would be that the feed linkage is frozen up. Nothing that a little WD-40 can’t take care of.

ReplyDeleteMy first guess would be that the feed dogs are packed with lint. So you’d need to remove the needle plate and clean any lint in the feed dog area.

My second guess would be to check the stitch length, which would be inside the left side cover. Loosen the screw and slide the indicator to about 2 1/2.

My third guess would be that the feed linkage is frozen up. Nothing that a little WD-40 can’t take care of.

Any chance you know where I can purchase the pins that go in a needle plate? It seems easy enough to just replace the pins. Mine bent and I have purchased two entire needle plates that don't fit well.

ReplyDeleteIt depends on what brand your serger is. I can get Bernina (and Juki) pins easily enough from Bernina. But any other brand I’d have to get from Brewer, and they just don’t exist through Brewer. Bernina pins are too thick to fit in other brands. So you’d need to call the dealer for your particular serger brand.

ReplyDeleteHello! I have had a pin on my Bernina 2000de come off. It's not bent and the needle plate looks good. How does one re-attach the pin? Thank you!! Susan

DeleteHi Susan,

DeleteYou can glue the pin back in with super glue or a 5 minute epoxy. The first thing I do is clean the grove out with a small screw driver. Then remove the parts off the back of the needle plate. Have a pair of big pliers handy – I like to use channel locks. Use a big pin to put a little glue all along the grove. Both pins should be sticking out about the same length. Then squeeze the pin into the groove with the pliers. Wipe away the excess glue – top and bottom. When the glue dries, you can scrape it off with your fingernail or a small screwdriver. Then put the parts back on the back of the needle plate.

Good luck with your repair!

Annette, I can't thank you enough for your quick reponse! I really like to fix things around the house and I'm very excited to have come across your blog. Your directions are great and I'm excited to tackle this repair! It was killing me to wait for a repair. Susan

DeleteHi, I have a Singer 5 thread that won't feed fabric unless I place upward pressure on the leading edge of the pressure foot with my finger. It doesn't matter what pressure foot I use, I have the same issue. The machine will not feed fabric on its own. Any ideas as to what is wrong? It is clean. The stitch length is set to normal as or all the other settings. I just received this machine (used); however, the previous owner swears it works. It is several years old and was only used 3 times. Thank you.

ReplyDeleteHi Vicky,

ReplyDeleteMy first guess would be that the presser foot tension is turned too low. The knob on the top, left side of your machine would be the presser foot tension. Turn that to the second from the highest number. My second guess would be that the presser foot shaft is gummed-up. A little WD-40 on the shaft would fix that pretty quick. One more thought would be the feed dogs may not be coming up high enough. I’ve seen needle plates packed with so much lint, they bow upwards, so the feed dogs are barely showing. I’ve seen some break, too. Another thing that keeps the fabric from feeding, is having burrs on the needle plate, stitch finger or support pins. Take the foot off and see what shape the needle plate is in. If there are rough spots, you can polish them with a very fine sandpaper (about 400-600 grit).

I hope you're able to get your serger going.

I took my serger into the shop and it is the needle plate. It will have to be replaced. Thank you so much!

DeleteI have a BabyLock SE200 that has been sitting in my closet for a (shameful) number of years. It was a gift all those years ago and I never really learned how to use it. It was used when I received it but had been serviced by my local sewing machine store. I pulled it out tonight hoping to watch some YouTube videos and figure out how to use it. I got the thing threaded and it seems to be working just fine motor-wise, but the feed dogs won't engage and move the fabric through. I lifted the presser foot to look at them and they don't do anything. I'm assuming that this many years of not being used the oil is all gunked up. I'm willing to spray a little WD-40 to see if I can get things moving, but I don't know WHERE to spray it. I'm not sure exactly what's supposed to move.

ReplyDeleteAlso, would you happen to know if any of the more modern machines have presser feet that are compatible? The feet I have are the snap in kind, so I wondered if I could use any feet of that type.

Thanks!

Hi Steph,

ReplyDeleteIf you remove the needle plate, you may be able to get to the feed dog linkage with the straw on the WD-40 can.

Most modern sergers have snap-on feet, but not all brands are compatible with each other.

Thank you for the reply. My son and I got inside the machine and sprayed WD40 on some random things and got it working again. Now to get the tension adjusted. Wish me luck! I just need some time to play with it. Thank you again for the time and effort you put in to answering everyone's questions.

DeleteI found the same serger for $20. at Goodwill. It has the exact same problem. I’m giving the wd40 a try and it seems to be working as the feed dogs are starting to move.

DeleteI have a singer serger. Was working fine but now the thread will not catch the fabric. Loops just fine without fabric...help?

ReplyDeleteHi Halen,

ReplyDeleteWhen a serger makes a chain without fabric, but not with fabric, there’s something that’s just a little off. First, replace both needles, then re-thread the serger and make sure everything is threaded like it should be, and be sure it isn’t tangling on the thread rack. Then check the tensions and make sure they haven’t been moved too high. It should be somewhere between 3.5 and 5.5. Next, make sure your needles are both pushed up as high as they can go. The needle on the right will be a little longer than the needle on the left. If that doesn’t fix the problem, then there’s a timing setting that’s off. Most repair shops charge $80 to $125 to time a serger. You have to decide if your machine is worth putting that much money into, or if you’d be better off putting your money on a better serger. With those Singer sergers, we can re-set the timing, but it’s very likely to go out again, pretty quickly. The quality of metal they use in those machines just can’t hold a timing setting.

Thank you. I have already tried with the threading, needles, etc...so I guess it's the timing.

ReplyDeleteHi I have a 5 thread singer server 14T967dc the machine will not chain thread anymore.I did have a jam which I cleared up now it will not chain is it possible one or both the loopers are off set?

ReplyDeleteI hate to say it, but Singer has no business making a 5-spool serger. If it’s new, take it back and get your money refunded. If it’s old, don’t put any more time or money into it. Get a new machine. OR, get a used Bernina or Juki or Huskylock or anything else. If you want a chain stitch machine, buy a chain stitch machine, not a 5-spool anything. If you want a cover lock machine, get a cover lock machine, not a 5-spool machine.

ReplyDeleteI recently picked up a singer professional 14u12 at a thrift store. The plastic has yellowed and it was pretty clear by the dust covering it that it hadn't been used in a while. Even so it looks decently taken care of and even had the manual so we got it.

ReplyDeleteI spent a couple hours today dusting/cleaning/oiling and re-threading it. And when I started it up it was super slow to start almost like it was locked up. After cranking the wheel a bit it started to run albeit slow but it had a perfect stitch on my little tester fabric. It never really picked up speed and then started to smoke. A lot of things I'm looking up are saying it's probably just dust or residue that needs to burn off, yet it worries me to do that if there could be something else going on.

I'm super handy with things is there anyway you could help me figure out which step I should take next? Should I open it up to see if it's just dust/old oil or should I try and see if I can "burn it off"?

I just don't want it blowing up on me but I'm confident if it's a somewhat simpler deep cleaning dusting I could handle it myself.

This comment has been removed by the author.

DeleteHi Christine,

ReplyDeleteIf it’s stiff to turn the handwheel by hand, then it needs a good dose of WD-40. If the handwheel turns easily, then it’s probably just the motor burning dust, and the smell should go away after it’s been used for a while.

Hi Annette!

ReplyDeleteI have a Brother 1034d that I use at least once a week. Today I was working with it and a pin head got caught between the presser foot at the very back and the feed dogs. I thought I had cleared the pin, but no. After I pulled everything out and started again, the machine was feeding the fabric verrrrry slowly, so that the serged edge looked like a satin stitch! The stitches looked perfect, just very close together. No change in the differential feed or presser foot pressure seemed to make a difference. I opened everything up and cleaned it out, still no difference. The feed dogs appear to be moving correctly and coming all the way out. Any thoughts?

Thanks!

Beth

Hi Beth,

ReplyDeleteDid you try to adjust the stitch length? I wonder if the pin head jammed the stitch length linkage. If adjusting the stitch length doesn’t make a difference, your machine will need to go to the shop. That ‘s something you don’t want to mess with.

I have a Bernette 334DS. It was serging perfectly the other night and then bam! it jammed up for seemingly no apparent reason. I have cleaned it, rethreaded, put in new needles, checked the plate pins, etc. I have watched the loopers move and they are both moving where they are suppose to, but it will not make a chain now. The thread moves through fine, just won't make a chain. Does this sound like a timing issue or something else? Much appreciate any help you can give before I have to resort to taking it in.

ReplyDeleteHi Melissa,

ReplyDeleteYes, it sounds like a timing issue. The first thing to check, is to make sure the needles are all the way up. The needle on the right should hang down a little lower than the left needle. If the needles are in right, and it still won’t form a stitch, then you’ll need to take it to the shop to have the timing adjusted.

Those old 334DS sergers are pretty great machines.

Good luck to you!

Thank you for all the help. I took her in and turns out it was the lower looper timing. They fixed her all up and now she is serging great!

ReplyDeleteHello! I have a Bernina 2000DE that was a hand-me-down from my MIL. I don't recall ever having two pins in my needleplate, but I did have one and it's gone AWOL. Do you sell parts or know where I can find them? I just need the pins from this plate, but all I'm finding is the complete plate for nearly $100. And Bernina doesn't even list this model on its site anymore. I'm desperate!

ReplyDeleteI managed to McGyver something out of a boutonniere pin and a doll needle, but I'm hoping to find something a little more secure. Any suggestions?

DeleteHi Indywriter,

DeleteI didn't see your comment until just now. The part number for the roll hem pin is 502010.00.79. That's the pointed one on the right. The stitch plate pin is 502010.00.43. Any Bernina dealer can order these for you and ship them.

Thanks so much for helping!! When I called my local dealer, they said these pins were parts for the 2000DCE and likely wouldn't fit my 2000DE. I know that these two machines have different needle plates, but do you think the same size pins will work? They'll order them for me, but won't take them back if they're the wrong size.

DeleteThanks again!!

Your posts don't come to my email for some reason.

DeleteAll of the Bernina stitch plate pins are interchangeable. They want to sell you a whole new needle plate. They probably have never replaced the pins on a serger, or they would know that! There are long pins and short pins. If the pin is too long, you can grind it down.

wow, you are awesome for sharing this info! thanks!

ReplyDeleteI do have a problem with my 25 year old Juki 634DE. Trying to find the reason for breaking Right needle thread led me to listen for frequent "tink" sounds, which led me to tutorials on timing, which led me to get out the magnifying glass to closely examine the workings of loopers, needles etc.

My problem is this: both needles are slightly askew. I'm unsure which is out of whack, but the Left needle is a slight footstep ahead of the Right needle (or perhaps the Right one is a small step behind). They are not both completely straight up and down.

This makes one hit the upper looper on the uptake, and the other hits the lower looper on the downswing.

I've tried 3 sets of brand new needles - Schmetz Universal 80/12 and 90/14 - and they all sit with this odd angle. I took out the tiny screws which hold the needles and one had a point on it, which I honed down just in case it was pushing the needle to one side, and have switched screws Right to Left and back; still the same angle.

Thinking that the needle holes need cleaning out...? Any ideas?

I'll be following you from now on!

Hi Sandra,

ReplyDeleteThe needles on a serger are supposed to be different lengths. If you hold your right hand out in front of you, and point your pointer and middle finger down (close the other fingers), that’s what your needles should look like. The right needle should be a little lower than the left needle.

If needles and loopers are “tink-ing” against each other, then the timing definitely needs to be adjusted. I don’t recommend that you try adjusting the timing yourself. It can get scrambled pretty quick if you don’t know what you’re doing.

I have a White 534 and the wicking string for the oil has broken so it won't oil the parts properly. Do you think I can just use any cotton string to replace it? And also, my hand wheel won't turn so where exactly do I clean out the gunk. (I actually have 3 White 534's because I love them).

ReplyDeleteI have an old White 534, too! One of the best back in its time!

ReplyDeleteThe wick inside the machine isn’t necessary. You can oil it manually if you remove the top and bottom covers.

If your handwheel doesn’t turn, your serger is probably frozen-up with old oil. Sergers are particularly susceptible to freezing-up if they aren’t used regularly. That’s when we use WD-40. If you have any of the wick in place, you need to keep the WD-40 off of the wick or it’s reservoir. Here’s a link to how I use WD-40 on sewing machines. http://shesasewingmachinemechanic.blogspot.com/2014/12/using-wd-40-on-sewing-machines.html You’d spray all of the metal parts that move. The difficult part is removing the WD-40. We use an air compressor. So if you have access to one, that works best.

Good luck to you!

I just bought a white 534 earlier today. The handwheel turns only once, backward or forward, it stops in the same spot. I've taken all the access panels off. I've oiled everything. It feels like it's hitting something that won't allow it to turn anymore. But I can't figure out what.

DeleteI'm sooo frustrated!

The machine looks almost brand new inside, my guess is it's only been used for one or 2 sewing projects.

I had this problem occur one time with my Elna, but I cannot for the life of me remember what it was or how I fixed it...

Please help!!!

And thank you in advance!

Hi C,

DeleteI’m afraid it’s probably the gear. If you take the bottom of the machine off, there’s a gear box cover that needs to come off, too. It’s a flat piece of sheet metal. Remove the screws, and you can probably see the cracked gear inside there.

The gear can be replaced, but it's likely to cost more than you paid for the machine.

This comment has been removed by the author.

DeleteI don't know whether I wanna laugh or cry right now... Lol! You were right. It took less than a minute to find it! I spent all night fiddling around with this machine.

DeleteSo disappointing!

I really appreciate your help tho!!!

It looks like it would be quite a job to replace it, even if I could get the part I need for cheap.

Thank you, this site is the most helpful! I have the same model and issue! Found parts and a service manual. Excited to tackle this job! Do you know of any timing tools out there that would help?

DeleteSome techs use measurements, some use sight. We use sight where I work.

DeleteFirst check the needle guard, under the needle plate. You’ll find it as you watch the needles going down at their lowest point. It’s like an upside down tunnel, with a guard in front and back of the needles. Make sure the needles aren’t deflecting off of it. It’s an easy adjustment, just loosen the screw, adjust it so there’s an equal distance between the front and back of the needles, then tighten it.

There are several timing settings on a serger. First, we check how the needle is working with the feed dogs. The needles should just be going inside the needle hole as the feed dogs are going under the needle plate. Second, the lower looper should come across the needles, just above the eyes. Third, the upper looper should meet the lower looper, passing very close to the bump on the back of the lower looper. When all of those settings are correct, then we work on the needle/looper distance and the upper looper/lower looper distance. They should be very close, but not deflecting.

Good Luck! And let me know if you need more help.

I got the part for the 534 serger. I have the set screws loosened all the way up the rod. I can't remove the rod out the back of the machine. Are there any e clamps holding the rod in place by the looper gear? I can get all the gears to spin freely from the rod. Thanks, Tina

DeleteI have a Bernina 2000DE. Its been working fine and all of a sudden the light started flashing when I press the pedal that useually indicates the looper door is open only it's closed. Is there anyway to reset it? I've tried unplugging, turning off then back on. I changed the needles, retreaded mutiple times and I just can figure it out. The manual says this light flashes when the looper door is open, presser foot is up or its set up incorrectly. I was sewing and stopped to change the fabric and this started. Thanks for your help!

ReplyDeleteHello Melanie. What did you do to fix this? We are having the same issue?

DeleteThanks!

Hi,

DeleteMelanie ended up buying a new serger.

She and her husband tried by-passing the switch, and it didn’t help. Which is why we suspect it was a problem with the circuit board, which you can’t get any more. The 2000DCE wasn’t one of Bernina’s better sergers.

If you’re looking for a great mechanical serger for a good price, you can’t beat the Juki 114D. It’s the same as a Bernina 800DL, and you can buy them for $499 to $549 on Amazon.

Hi Melanie,

ReplyDeleteMy first thought is that the door needs to be adjusted. If you look inside the door, you'll see screws that hold the door on. They're adjustable -- side to side and front to back. The spring loaded rod may not be connecting with the switch that's in the side door. When you open the side door, there's a cable that comes around to the front. These two need to make a complete connection.

So I pressed on the bottom front of the door and it started to run perfect again and then it stopped after maybe a minuite. I completely took the door off of the spring loaded rod and reconnected everything making sure it was all nice and tight and the light is still flashing like the looper door is open even when it's not. I'm not sure why pressing it hard at the bottom worked earlier but it did only temporary though. I'm not an expert but pretty handy with tools. Is there a switch that could be bad that is part of the door. Its a bernina 2000DE. It sewed and ran beautiful until today. Any other suggestions? Thanks for your help!

ReplyDeleteI do not have a cable. Only a spring loaded rod at the bottom of the door.

ReplyDeleteThe cable is in the left SIDE door.

ReplyDeleteWhen you say the light is flashing, is it an icon on the screen or the light bulb? Do we need to put a new light bulb in? Do we need to check the foot control and cord? The power switch can get lint in it and won’t let it go when you push the foot control, until the lint is gone.

What do you think?

It's the saftey switch light that indicates the looper door is open. The bulb is working for the main light. The needles are new the foot is down. Its an issue with the safety switch that says the looper door is closed. I do not have a left side door on the 2000DE only the front looper door. My bernina bernetteDS has a left door but not this one.

ReplyDeleteIt's an icon just above the needle down button. My hubby opened up the front of the machine and says the switch for the door control is good. The only other thing I can think of us the foot pedal?? Would it cause the light to flash? It was working fine earlier and just quit then worked for a minute after pressing real hard on the lower part of the door. Maybe that had nothing to do with it? The power supply and foot pedal are seperate on this machine. The lights all work so it's definitely getting power.

ReplyDeleteMy apologies, I got my Bernina sergers mixed up.

ReplyDeleteSo I looked up the schematic on your 2000DE, and I can’t find the safety switch. There’s a circuit board inside. I know you can’t get that circuit board any more, and I know it’s notorious for blowing out. If we could find the safety switch, we could probably by-pass it. There are 3 places it could be. 1) right behind the front cover, where the door is connected in the middle. 2) where the top of the door latches on the top, right side. Or 3) under the machine on the right side, next to the door.

Can you see where it connects to a switch?

Correct it's under the door on the right side. We've found the switch my hubby took the cover off.

ReplyDeleteHe bypassed it already with a jumper wire and it did not work :(

ReplyDeleteDarn! That makes me think it's probably the circuit board.

ReplyDeleteI bought a new one. Its ashamed because this is a pristine serger that sews beautifully. The inside and out are immaculate. Its been used maybe you 10 hours....maybe I can find a hand person who can fix it to take it off my hands.

ReplyDeleteA new serger is probably the better way to go. The Bernina 2000DE wasn't one of Bernina's better sergers.

ReplyDeleteYou gave it a great try!

Thank you very much for sharing this :)

ReplyDeleteHello!

ReplyDeleteI have a brother 1034D and I've wasted probably 10 needles trying to fix this issue. The problem started as just one of the loopers not catching so I changed from 4 to 3 threads, cleaned it, replaced the needle, and it was fine for what I'd been sewing. Switched to another project and returned to 4 threads. It was okay for a good few hours then again one of the loopers started skipping. Re threaded, cleaned it out with air and again it was fine for a bit. But once again it wasn't catching, this time it was the upper looper and no matter what I did it wasn't working. Went to the store, bought new needles and worked for a moment. Now it's not chaining, the lower looper is scraping the plate, and the right needle keeps chipping just at the very tip. Happened 3 times, no matter what I did. Is it even salvageable? Or worth repairing? Or should I just purchase a new machine?

I sew almost daily, mostly cotton and rayon but a lot of gathered material so it can get thick. The machine handled it pretty well for the last 6 months until just now. My regular sewing machine is a commercial grade Viking and the serger was really just to add a cleaner finishing touch to my garments. If it is not worth it trying to fix what are your recommendations for machines around $500-$800?

The timing is probably out on your serger. And you could take it to the shop and have it adjusted, but it will go out again. The metal in those sergers can’t hold a timing setting. The other problem with that particular serger is the thread extender doesn’t go up very high, so the thread catches on the bottom of the spool and makes an uneven stitch.

ReplyDeleteCheap thread can also give you a bad stitch. Always just use Maxilock.

If you’re serging on heavier fabrics, you probably should invest in a stronger serger. But keep in mind that no serger should do things like sew over a flat-feld seam in denim. That will throw the timing off or break the loopers.

Juki used to make the Bernina sergers. But for some reason, Bernina quit having Juki make them, so now the new Bernina sergers are pretty bad. The good side of this is that Juki is putting out the good Bernina sergers as Jukis. You can get them for $499 on Amazon. They are model MO114D and MO104D. The 114 has the controls on the outside of the machine, and easier access to thread the lower looper.

Thanks so much for replying!

DeleteWhat are you thoughts on a Janome or the Huskylock s25? I've tried them in store and quite liked them but what about longevity and overall quality?

What do I do with the brother? I'd hate for it to just go to waste by tossing it or putting it in storage. I'd prefer to give it to someone willing to repair it or a shop that refurbishes, but I don't know of places that do that.

I still like the Jukis better than Janome or Huskylock. They’re just made very well. Although some Huskylocks have the front presser foot lever, that’s really nice.

ReplyDeleteThe Brother will just be a headache for someone else. I wouldn’t take it to the thrift store or give it to someone. You could strip the parts off and try to sell them on Ebay. Or donate it to a local repair shop for parts.

Any tips on breakibg loose factory set lower looper needle screw? I have to replace mine. Singer serger, cheaper model :(

ReplyDeleteHoping you can help before I throw my serger at the wall lol. I have a brother 1034d serger. I had something get stuck the other day and ever since I can't get it to serge right. I've don't just about everything and tried all the advice I've gotten. The very left needle is missing whenever the trension is above 5. I think it might be the lower looper not catching it. It's just so weird because at 5 and under it stitches fine except that is just too loose for me. When I opene the seam the thread is showing way too much. Anything above a 5 that left needle is skipping.

ReplyDeleteHi Bobbie,

ReplyDeleteFist thought is that the timing is off just a little. Second thought is that there may be a burr on one of the loopers or on the needle plate pins.

I had a serger in the shop today that was doing the same thing yours was. It turned out to be a burr on the upper looper and the needles were hitting on the needle guard that’s under the needle plate.

I hope it’s something simple, and that you can get back to sewing.

Hello, I "inherited" a serger that my Aunt says she only figured out how to use once, and her and her daughter both said "good luck" when I took it home. It is filthy. It was sitting either in her garage or basement probably for years. I can't really complain because she gave it to me, but I'd rather not bring it to get serviced until I give it a good cleaning myself first. I haven't even turned it on yet. It's a simplicity sw432 (I know it's old and uncommon because there is next to nothing about them online...). Every part of it has some dust on it. I don't think it was actually used much, so I don't think the blades would have dulled or anything inside would have been overused and need replacing. Do you think I can give it a decent cleaning and have it work alright? Or does it sound like it would be beyond home cleaning? There isn't anything electronic about it, I really think it just needs a head to toe deep clean. Thoughts? -Catie catiepauline@gmail.com

ReplyDeletei have that same serger i got at a thrift shop. i kind of fixed the timing on my machine but i lost the knob that is on top of the serger right next to the clear white caped thing... try to clean it up it might be worth it to fix it yourself. I wont find out now since i can not find a replacement part i need to be able to use it.

DeleteHi Catie,

ReplyDeleteIt’s certainly worth a try. You can clean the outside with glass cleaner. Then remove the bottom of the serger. There should be 3 – 8 screws to remove. Usually, you don’t have to unscrew the foot pads. Then remove the left side above the needle, and the left side below the feed dogs. If you have access to an air compressor, blow it out real good. If not, use a lint brush and canned air.

If it’s frozen up (you can’t turn the handwheel), you’ll need to spray all of the insides with WD-40. Work it in until the machine is running smoothly. Then remove the WD-40 with rags and air. Then re-oil with a good “sewing machine oil” or “Tri-Flo Superior Lubricant.”

Once you’ve got it running smoothly, put it back together. Check and repair the needle plate if, needed. Replace the needles and thread the machine. Remember that you have to thread a serger in the right order or it won’t sew. If the threads are numbered from left to right, start with #3, then #4, then #2 and #1.

Set all of the tensions to their “normal” setting (if it’s not labeled on the dial, start at 3). Give it a sew and see what happens.

Let me know if I can help further.

Good Luck to you!

Thank you so much for your quick reply. I made sure to print out the manual and read all about threading in proper order. I will give the deep cleaning a go and see what happens. Thanks again!

ReplyDeleteI have a Brother 5234PRW. I was serging away happily when everything seized up. When I looked inside the front cover I could see that a piece of thread that was cut off the fabric got caught in the lower looper shaft. I tried pulling it out with tweezers, but couldn't get it. The Hand wheel won't turn in either direction. Is there anything I can do to get it out or am I destined for a trip to the repair shop?

ReplyDeleteHi Karen,

ReplyDeleteIf you’ve got some small scissors with a sharp point, or a seam ripper, you might be able to get it out. Can you take the needle plate off? Looks like it only has one screw to hold it on.

If you can get the tangle out of there, that’s great. But… if it seized up, the timing may be off. So take it slow. When you get the tangle out, turn the handwheel by hand before you step on the foot control. If anything is crashing together, you need to take it to the shop. If not… Happy Sewing!

Hi there, The foot pedal of my Bernette 334DS has decided to stop talking to my machine. I did a test overlock(I don't often sew) and all was well. I have now cut out 4 cushions to make, the serger does not work at all. All lights on etc. Any advice?

ReplyDeleteHi Flick,

ReplyDeleteUsually the problem is in the cord, either leading into the machine, or leading into the foot control, or leading into the wall socket. To test which it might be, plug it in with the switch on. Then press the foot control all the way down and wiggle the cord. If the power comes on when you wiggle it at any of the 3 spots, then you know where the break is. The break will be inside the cord and won’t be visible by just looking at it. You may be able to get the cord in the right position to make it work for a while. But you will most likely have to replace it. The sad thing is that it’s very hard to find a replacement. Bernina and Brewer don’t carry them any more. You can probably find a used one on Ebay, but you won’t know how long it will last.

A couple other possibilities are that the motor or just the mechanics of the machine could be frozen up. It’s not very likely to be the motor. If you turn the handwheel and it’s really stiff, it’s likely that the old oil that has frozen up the whole machine. That’s a job for WD-40!

It’s a great serger! I hope you’re able to get it going.

Help, please. I’m trying to figure out how to put a new thread holder on a Bernette 334DS. I have two & trying to make one good one for a friend. Can you instruct me how to go about this? Please.

ReplyDeleteHelp, please. I’m trying to figure out how to put a new thread holder on a Bernette 334DS. I have two & trying to make one good one for a friend. Can you instruct me how to go about this? Please.

ReplyDeleteHi Rose,

ReplyDeleteThe most important thing about serger thread racks, is that the thread needs to pull straight up from the top of the cone.

A lot of times, we use a Dermal tool with a file bit to cut and drill holes. It takes a steady hand. I try to brace my hand against my hip to get the best control. Are you taking the spool pins off of one and putting them on another? I’ve decided my favorite epoxy is Clear JB Weld (5 minute). It works great for this kind of thing.

Bless your heart.. My serger works again, thanks to your advice. It was looping terribly on the underside of the fabric. I took off the throat plate, & checked the pins - both there and in good shape - and I had cleaned it not too long ago, so there wasn't much dust/fuzz. I checked the needle positions & I think I raised the left one slightly, and I made sure my thread was coming straight up off of the cones (it wasn't, so I fixed that. Mine didn't have a sticker or anything to indicate which way the arm should face.) I ran a scrap of fabric through, and... No more loops! Yay! Thanks so much! You rock!

ReplyDeleteHi Laura,

ReplyDeleteThat’s Awesome!

Have fun sewing!

Hey Laura...I've spent about an hour reading through this post to see if there was anything here to help me with my problem, but didn't see it...hope you can help me!

ReplyDeleteI have a Singer 14SH654 - my first serger ever, and I love it, but I've done something horribly wrong...I was sewing with denim and it got jammed up...took forever to get it out, but in the end, I think I've bent the lower looper. The needle is in front of the lower looper, but hits the lower looper on the down stroke, and ends up behind the looper on the upstroke. I know nothing about how this should work, being such a newbie...can you provide some guidance? TIA!

Hello,

ReplyDeleteIf you’d like to try to set your timing, I can try to help you. However, there are a few timing settings, and there may be more than one setting that’s off.

If the looper is bent it will need to be replaced. If it’s just knocked out of time you might be able to fix it.

There’s a bolt/screw at the bottom of the lower looper that holds it onto the shaft. If you loosen it, you can move the whole arm. The lower looper should pass behind the needles and the tip should be just above the eye of the needles. The loopers should only have a tiny space between them, but they should “nest” together. I’ve attached some pictures.

Good Luck! Let me know how you’re doing.

Thanks! I didn't see the pictures, but I determined that the timing is way off - the needles are hitting the looper on the downstroke about half-way on the looper - the tip of the looper is far to the right on the upstroke! I tried adjusting just the bolt/screw, but it didn't help. I've rounded up the correct size hex driver but think I'll need to remove the bottom cover to get to it. I know, it won't be just a simple matter of removing the bottom, it's always a puzzle! Thanks for the reply - it helps just to know you're not alone! I'll let you know how it goes!

ReplyDeleteHi, I have Huskeylock 910. Yes, it is old, however always has worked with no problem. It is jamming, can’t turn the wheel. Now and then it will move and sew about a foot, then jam. I have cleaned and oiled, it is noisy as well.

ReplyDeleteWhen you say that you’ve cleaned and oiled, have you taken the bottom off of the machine? I believe that particular machine has some wires in the base that need special care if you remove the bottom. So if you do remove the bottom, be very observant to get things put back into place.

DeleteIt sounds like it really needs a deep clean. When sergers sit un-used, the old oil inside turns into a tar. The hotter the machine gets, the tighter it will bind up. The bottom needs to come off, and we need to remove the old grease and oil, and put some clean grease and oil back on. With your machine, special care needs to be given to protect the circuit boards and cables. I suggest that you don’t do this one yourself, but take it to a Viking/Husqvarna dealer.

Thanks so much.

DeleteSounds like the old lubricant may need to be completely removed. The jamming could be a bent cam. Spend the $$ and take it to be serviced. Best $80 I ever spent.

ReplyDeleteI have a babylock 5260, it was my grandmothers. It will serge fine, stitches look great then it will bog down out of now where and almost come to a stop. Any ideas on what could be wrong? Thank you in advance for any help!

ReplyDeleteSounds like it just needs a good cleaning. When a serger sits unused for a while, the old oil will turn into tar. We have to go inside and remove the old oil with a solvent, then put clean oil back in.

ReplyDeleteThank you for the quick response. We will give it a try, there are no service centers in our area. Wish me luck:)

ReplyDeleteThank you so much for this post; it's the most helpful thing on the internet about sergers!

ReplyDeleteI would love some help figuring out how to get the timing right on my 5-thread Singer Quantumlock 14T967dc. I've been working on it for the better part of a week now. I was using a two thread coverstitch and when I switched back to a four thread ultra mock safety stitch, the upper looper kept hitting the needles.

So at this point I've changed just about everything and it seems to be moving correctly except that the lower looper isn't picking up the left needle thread unless I turn the tension all the way down. The right needle is consistently picked up, but forms a loop on the bottom of the fabric (although I don't know if that's because everything else is wonky).

My thoughts are either that the needles are down too far (and thus the thread is too taught for the looper to catch) when the lower looper begins to pass behind them, or the position isn't correct and the lower looper needs to be further to the right when the needles begin to move back up. Is there anything you can tell me about the relationship between the needle position in relation to the lower looper and where it should be when the needles are completely down?

I am almost positive at this point that I will be buying a different serger, but I've spent so much time inside of this one that I'd really like to fix it just to prove that I can. If nothing else, I have learned a LOT about how sergers work! Thank you!!

Often, when everything looks like it should, the one adjustment that might be missing is the needle bar needs to be twisted so it’s closer to the left needle. There’s usually a screw you can get to from the left side of the machine. Sometimes you have to remove the light to get to it. You have to get the needle bar in its highest position, then loosen the screw. Grab the needle bar just above the needles and turn it side to side until both needles are equally close to the upper looper, but not touching it.

ReplyDeleteGive that a try and let me know what happens.

Juki has a great serger on Amazon for only $499. It’s model 104 or 114. The 114 is nicer, and worth the $50 difference. Juki used to make Bernina’s sergers, but they had a parting of the ways, and now the “Bernina” sergers are selling for half the price with the Juki name on it.

Thanks, I've tried adjusting the needles and they seem to be lined up. I changed to new ones just to be sure. Same mixed results. I also tried changing the timing a bit left and right with the lower looper and still can't quite figure it out. Maybe I messed up the tension or something because everything turns out pretty loopy even when I turn them up. Three thread overlock looks perfect, though, so I am pretty baffled.

ReplyDeleteIf there are loops and changing the tension doesn’t work, the tension has a problem. A lot of times, the thread looks like it’s in the tension, and it isn’t. Try pulling the thread out of the tension and watch to make sure it goes between the disks. Then pull both ends of the thread so it goes all the way into the tension.

ReplyDeleteI have a Huskylock 910. Had it about 10 years and don't use it alot but love it when I do. Went to use it (been about 6 mos since last used) and can't get it to form stitches. Machine runs. Rethreaded it about 4 times, changed the needles, cleaned what lint I could (removed important parts). It still won't make a chain.

ReplyDeleteHi Ginny,

ReplyDeleteIt was forming a chain last time you used it, so what could have changed? Are you sure you’ve got regular needles (130 705H, not industrials) in it, with the flat side to the back? And you threaded the loopers first, then the needles? Are you using Maxilock thread or kite string?

There’s got to be some little thing that’s missing. Or somehow the timing got knocked out.

Let me know if you figure it out.

I just purchased a used brother 1034d and the feeddogs wont work. The fabric just stays in place. I have tightened and loosed the upper pressure but it still won't work. It looks like the lower feeddogs are not up high enough to catch the fabric at all. Do you know where the adjustment is for the lower feeddogs.

ReplyDeleteOn a serger, when the feed dogs aren’t high enough, it usually means that they’re packed with lint. Remove the needle plate and clean the lint out. If that’s not the problem, check the differential feed knob and the stitch length knob on the left side of the machine. They have “normal” marked on both knobs.

ReplyDeleteLet me know what you figure out.

Had machine apart. There is no lint. Played with all the buttons and settings and nothing will make the fabric move at all. It is like the feeddogs are too low and won't grab the fabric at all.

DeleteHello, I have a Babylock BLSE200. It does a 4-thread overlock just fine, if there is fabric. Without fabric, it will not create a chain. The thread will come out, but when the next piece of fabric hits the needles, it does not create an overlock for about ½ inch. After that it works fine. To avoid the problem, I have been running water soluble stabilizer between pieces of fabric. I have made several garments this way, having changed thread and needles between garments. Any idea how to fix this? Thanks, Cindy

ReplyDeleteHi having trouble with my Janome my lock not making chain just sewing in same spot getting jammed I've checked and re checked the threading etc can seem to find the problem googled and google please help

ReplyDeleteFirst, adjust the stitch length. The average stitch length is 2.5 and gets longer with a higher number.

ReplyDeleteSecond, remove the presser foot and look at the pins on the needle plate. Are they damaged? If they've got burrs, you can polish them off with a very fine sandpaper (400 to 500 grit). If the pins are bent, and you can't straighten them, you'll have to buy a new needle plate.

Third, remove the needle plate and clean out all of the lint around the feed dogs. I've seen machines that have been so packed with lint, that the feed dogs can't come up anymore.

I hope you're able to get your serger sewing again!

I have a Brother. The lower looper needle broke. Is this something I can replace myself? They want almost as much money to fix it as to buy a new one. So, it is sitting unused at the moment and I am very frustrated,

ReplyDeleteI have a Juki 655 serger and the upper looper won't move. Not sure what I did wrong it chains fine but it will not flat lock or wrap the thread around the fabric. I've had it close to 2 yrs. I can send it back for free work but I can't help thinking its just something little. I had all 5 spools in it before this using the chaining and overlock function. But usually just 3 spools.

ReplyDeleteI figured it out I engaged the upper looper. I had disengaged it to just chain stitch.

DeleteHi Annette, I have an Elna 664 PRO. Recently the tension discs for both looper threads haven't been holding much tension. I have had to set them both at about 8, while both needle tensions are set at about 4 (a few months ago, all 4 tension discs were working well set at 4 each). I'm assuming, based on a little research I've done, that either the tension discs assemblies and/or springs (??) need to be replaced. In your opinion, is this a repair that a lay person should attempt, or would I be better served at having this done by a professional? Thanks in advance for your time!

ReplyDeleteHi, on my singer serger I was re-threading it and I think i cranked the hand wheel the wrong way (i'm used to my reg. sewing machine) now it's sticky and motor runs but needle will not move-anyway i can fix this? LMK-thanks!

ReplyDeleteHi, on my singer serger I was re-threading it and I think i cranked the hand wheel the wrong way (i'm used to my reg. sewing machine) now it's sticky and motor runs but needle will not move-anyway i can fix this? LMK-thanks!

ReplyDelete:-) Thank you for the pictures and explanation. My upper looper rod rotated too far down and was binding causing no loops at all.

ReplyDeleteI'm a mechanic. If I can't fix stuff I don't want it. Also, I live on a boat a cruise distant shores. A machine that doesn't work goes overboard. I was really put out that Bernina wouldn't share the repair and adjustment manual with me. I also have a Sailrite and the provide online video of every adjustment there is. I'm back in business with a beautiful trail of loops.

Wow, what a great website! Thanks for all the info.

ReplyDeleteHello,

ReplyDeleteI have one of those old U14 Series 5 thread Singers. It's about 25 years old. I have never used more than one needle b/c I use it only to finish edges. It has always had a problem of a clunking sound and then skipping stitches when sewing heavy or multilayered fabric. It does fine on thinner fabric. I keep it oiled and clean and have never played with any of the adjustments b/c the screws are way too tight so I never considered it to be a timing issue. I also never knew about the pins in the needle plate b/c this model doesnt have pins in the needle plate. It has only a very short projection of metal where the pins would be. I never noticed that this piece was missing on my needle plate because I dont know that I ever noticed that it was there in the first place, if you know what I mean. Is this projection what you are calling a needle guard? Could this missing projection be the cause of skipped stitching even when ony using one needle? Here's a picture of the needle plate as it should look. Their picture is upside down: http://www.sewvacdirect.com/serger-needle-plate-fits-singer-14u34-14u44-and-more/ Any help would be most appreciated.

Hi. I was wondering if you could help me with my brother 934d serger problem? I had to replace the lower looper and to get it the right height, I am to use a gauge but I can not find any info on what the name actually is where to get one. I know its an older serger and maybe they don't make the gauge for it any longer. Is there another way to do the measuring of it than the gauge? Thank you.

ReplyDeleteWhat a fabulous post! My old Babylock seizes up after a few inches of stitching. Now I know, thanks to you, that the lube in the flywheel is probably gummy since I haven't used my machine in years (I know, slap my fingers for that!). I think I can see how to take it apart - so I'm going to give it a try.

ReplyDeleteI'd love to know where you are located. If you are in Utah, I'll be there in the fall for a week or so and would love to have you service my machines.

I have a White speedylock differential model 1500.The differential feed (with the teeth) broke and although I super glued it once ..it came apart again and I can find no replacement part anywhere. Otherwise the machine worked fine.Any ideas or do I just scrap it?

ReplyDeleteI have a White speedylock Differential Model 1500. The differential feed (the metal part with the teeth) broke and although I super glued it once (and it worked a while) I broke apart and I can't find a replacement Anywhere(: An ideas or do I just scrap it?

ReplyDeleteI have a brother 1034D surger. It's about three years old. I have only used it a handfull of times. I pulled it out to use it and it wouldn't go. No noise or movement at all. I've tried a different outlet and a different pedal, the peddle worked on another brother machine I have. What could be the problem? Thanks for your help.

ReplyDeleteHi, I have a Europro Model 534DX serger. I took it to a repair shop over a year ago because it was skipping stitches--the looper threads were't always getting caught by the left needle. I hope that makes sense. The repairman said there was nothing wrong with it, but that I was using bad thread. So I got the thread they recommended and it is still doing this. They maintained that they could see nothing wrong with it. I'm trying to decide if I should try a different repair shop, or if I should just scrap it and get a new serger. Are you familiar with Europro machines? What would you recommend?

ReplyDeleteThanks!

I’m not sure if you’re still around, or if you took a break from the many voices crying out for help in the serger wilderness. (Understandable since this is a great resource and sergers are a pain in the bum.

ReplyDeleteIf you are around and have a moment: We have a Huskylock s25 which came to us with a non-functional touchscreen. In a last ditch effort, I took it apart, found the connection that wasn’t working, and fixed the touchscreen. I know we lucked out there in not needing to replace it (or sell for parts... yet).

But ever since putting the body back together, I get a front cover open error whenever I try to sew. I tried manually toggling the switch on the bottom right inside the door, but I get the same error.

Any idea what the heck I did? The serger did serge before I took it apart, but it was stuck in 5 thread safety wide and the lowest contrast setting. I double checked all of the chassis seams and everything SEEMS flush.

Thank you in advance for any assistance.

"She's a sewing machine mechanic" what a great, helpful, kind person you are. Sorry to see you not around anymore.

ReplyDeleteThanks for the advice!! I have a BL 5260D. I inherited it. What is the knob in the left end with the red arrow for. I have no manual .i can not move it does it take a special tool. I can make a chain but feed dogs not moving. Got some WD40 going to try it. How do I set stitch lenght too.thank you so much.

ReplyDeleteI do have a SIMPLICITY EASY LOCK 880 serger machine but its sewing backward

ReplyDeleteWow! A serger sewing backwards isn't something you run into every day!

ReplyDeleteMy first thought is that something in the feed system could be gummed up. WD-40 could probably fix that.

However, if someone has loosened screws that they don't know what they do, it could have scrambled the feed system.

Hmmmm....

PS: The Boss would say, "It's OK, just turn the machine around."

ReplyDeleteHi 👋🏻 I have a jukiMo-655 upper looper bar is not moving at all, at first everthing was jammed handwheel would only turn 25% so I loosened the small screw under the looper bar.... now all the gears and handwheel move freely except for that darn upper looper bar HELP! Any thoughts would really be appreciated,thanks

ReplyDeleteSometimes, it isn’t that anything is out of place, it’s usually just frozen with old oil that has turned into tar. If you can work some WD-40 into the upper looper shaft, and internal works, that usually is what it needs. Remember that you have to completely remove the WD-40 after it does its job. Here’s a link to using WD-40 on sewing machines. http://shesasewingmachinemechanic.blogspot.com/2014/12/using-wd-40-on-sewing-machines.html

ReplyDeleteGood Luck to You!

I have a white superlock 534 sewing backwards. I can't figure out how to make it stay forward feeding. I blew it out, and tried to get it to feed forward. I opened the left panel and adusted the cam so the feed dogs were going the correct direction as I turned the wheel. About 2 rounds and it shifts back into feeding backwards again. IvI' taken the bottom plate off to see if there was something loose or missing. Nothing! Okay a bit of lint and I blew that. The arm that holds the stitch kengle adjustment cam in place had about 1/16" play in it and seemed to catch so I tightened it up so the play was out, but still moved free.

ReplyDeleteWith a bit more digging I discovered the set screws for the cam were loose allowing it to flop around. Tightened them up, added a 3rd washer to the adjustment screw (was sliding) and now she's working like a champ. Just need to finish setting thread tension. Top to bottom left to right 4,2,3,3 didn't work so am at 7,4,4,5. Better, but not quite there. I will change thread color so it's easier to see what's really going on with it.

DeleteWow! You found the problem and figured it out! You did awesome! You’d make a great sewing machine mechanic.

DeleteMy Bernette 004_D unlock server was working just fine I was sewing the edges of some old towels making rags when all of a sudden I heard a fast humming sound. I checked the belt it's just fine, took the bottom of the machine off there us no second belt or fragments of a second belt. The motor hums but nothing is working.

ReplyDeleteIf the motor is humming when you’re not pushing the foot control, that usually means that the foot control is partially engaged, which is a fire hazard! You need to open the foot control and adjust it so the contacts don’t make contact until you press the foot control down. Some foot controls have a “potentiometer” that can be adjusted. It looks like a metal circle with a screw driver slot in it that can be turned to adjust how quickly the switch is kicked-in. Others have a thin metal piece that can be bent.

DeleteGood luck to you! Let me know if you’re able to adjust it!

Hello Annette

ReplyDeleteCould you advise about overlockers please. I have a toyota 5000 that has recently been serviced and works fine and also a Bernina record 830 which I am learning how to use. I am choosing mainly woven fabrics to work with that fray a lot and I like garments to look neat on the inside. I have been using zig-zag stitch so far. Would it be an idea to get a serger and if so what reconditioned one would you suggest.

If you can find a refurbished Bernette Serger model 334DS, that’s a great machine. Not as strong as the newer machines, but has differential feed. You can get a brand new Juki 104D for about $450 to $500. The Juki 114DS is the same machine, only it’s got the knobs in more convenient places, and you can thread the lower looper from the front door area. At my store, we sell those for $50 more. Juki 654 is a great model. Bernina 700D or 800DL are great models. Avoid the Bernette 100 series and 2000. Bernina 006 or 007 are good, but make sure they are the “D” models that have differential feed.

DeleteHello Annette!! I have a Simplicity SL370 serger that is skipping a stitch every once in a while. I bought a new needle plate, and have adjusted everything I can think of, do you have any ideas?

ReplyDeleteHi Nancy,

DeleteThe first thing to check are the needles. Make sure they’re pushed all the way up.

Second, is what kind of thread are you using? Maxilock is the best. If your thread gets twists in it as it feeds through the tensions, it will make you skip a stitch.

Third… your thread mast is really short. You could put your threads on the floor behind the serger in heavy mugs or canning jars. Then they would feed into the machine much better.

If those are all OK, there’s probably a timing setting that’s a little off. If you’ll remove the needle plate and turn the handwheel (there’s an arrow on the handwheel to show which way to turn it), and watch to see if the needles or loopers deflect off each other or the needle guard. If something is deflecting, that’s the thing that needs tweaking. It’s OK if they brush each other, but not OK if they deflect off something.

I hope you’re able to get your serger sewing well again.

Working on a 774 hobby lock. The timing was messed up. Got a copy of the repair manual. Have not been been able to get it to work properly. My question the first step is to align three of the cams to the surface of the drive shaft. It mentions the first screw but the illusion indicates the second screw. Which is it and I figure surface means up.

ReplyDeleteSome techs use service manuals and measurements, some use sight. We use sight and no service manuals where I work. So when you say, “align three of the cams to the surface of the drive shaft,” it doesn’t mean anything to me. We work with the needle bar, feed dogs, loopers and needle guard.

DeleteFirst check the needle guard, under the needle plate. You’ll find it as you watch the needles going down at their lowest point. It’s like an upside down tunnel, with a guard in front and back of the needles. Make sure the needles aren’t deflecting off of it. It’s an easy adjustment, just loosen the screw, adjust it so there’s an equal distance between the front and back of the needles, then tighten it.

There are several timing settings on a serger. First, we check how the needle is working with the feed dogs. The needles should just be going inside the needle hole as the feed dogs are going under the needle plate. Second, the lower looper should come across the needles, just above the eyes. Third, the upper looper should meet the lower looper, passing very close to the bump on the back of the lower looper. When all of those settings are correct, then we work on the needle/looper distance and the upper looper/lower looper distance. They should be very close, almost touching, but not deflecting.

Good Luck! And let me know if you need more help.

Thank you. Will give it another try. Maybe third time will be the charm

ReplyDeleteI have a Kenmore 3/4D Serger model 385.16655100 & it has performed great until I got a knitted piece jammed down in the loopers. 😩 I totally lost patience & finally grabbed & ripped that out of there. 😣 it doesn't make the serg at all now. I know..serves me right. It's out of wack real bad so I doubt I can make it any worse, so I would please appreciate if I could get pics or schematic of where the timing should be & what is the black metal piece that is screwed on to the lower looper stem in front of & below the looper needle. It is kind of a U shape if looking from above & one part of the U bends down..i broke part of that U off.😲

ReplyDeleteI also have my Moms old NECCHILOCK. In which you can actually do a separate chain stitch instead of a overclock. That will work on very light fabric but you get any weight to the material at all it just sits & slips..at least that's what it sounds like.

ReplyDeleteKenmore is very protective of it’s parts info, so I don’t have access to a schematic or parts list. You’d have to take it to Sears and have them get you a part. However, I don’t think there are any more Sears stores that service sewing machines.

DeleteThe upside down U is the needle guard.

Some techs use measurements, some use sight. We use sight where I work. Here’s how we do it…

(I know your needle guard is broken off, but you’ll have to replace it if you want to get it working.) First check the needle guard, under the needle plate. You’ll find it as you watch the needles going down at their lowest point. It’s like an upside down tunnel, with a guard in front and back of the needles. Make sure the needles aren’t deflecting off of it. It’s an easy adjustment, just loosen the screw, adjust it so there’s an equal distance between the front and back of the needles, then tighten it.

There are several timing settings on a serger. First, we check how the needle is working with the feed dogs. The needles should just be going inside the needle hole as the feed dogs are going under the needle plate. Second, the lower looper should come across the needles, just above the eyes. Third, the upper looper should meet the lower looper, passing very close to the bump on the back of the lower looper. When all of those settings are correct, then we work on the needle/looper distance and the upper looper/lower looper distance. They should be very close, but not deflecting.

So… If you can’t get the part, I recommend the Juki 114D as a great replacement, at a great price.

The Necchi chainstitch machine is a persnickety little machine. We usually tell people not to waste any time or money on fixing them.

Good Luck to You!

I have a Kenmore 3/4D Serger model 385.16655100 & it has performed great until I got a knitted piece jammed down in the loopers. �� I totally lost patience & finally grabbed & ripped that out of there. �� it doesn't make the serg at all now. I know..serves me right. It's out of wack real bad so I doubt I can make it any worse, so I would please appreciate if I could get pics or schematic of where the timing should be & what is the black metal piece that is screwed on to the lower looper stem in front of & below the looper needle. It is kind of a U shape if looking from above & one part of the U bends down..i broke part of that U off.��

ReplyDeleteThank you & I appreciate your help & description of how the loopers & needles should look at specific stages.

ReplyDeleteI guess I need to Google any Kenmore online parts services. That U piece comes right off by unscrewing the Phillips head screws. Thanks again.

Check this out..its where it shows all the schematic for my Kenmore serger: https://www.searspartsdirect.com/model-number/38516655100/0582/1220000.html

ReplyDeleteAnd you can download the PDF pages. Also has the prices for all the parts ��

Wow! What a great resource!

Delete����

DeleteHey there! I have a Juki mo-50eN serger. My thread will not stay seated in the tension disc for my left needle at all while I’m sewing. I can stop, retread, making sure it’s seated, then while sewing it slides right back out! While threading, I have my tension set at 0, then tighten after threading each one. What’s going on!

ReplyDelete*Feeling Frustrated ��

Hi Lish,

DeleteMy first thought is maybe it’s the thread. I’ve seen thread twist until it forms a loop, then it pops out of the tension. You can watch it as you’re sewing and see if that’s the problem. The best thread for serging is Maxilock.

I’ve also seen a faulty thread guide that won’t hold the thread in. You can tape a paper clip to the serger and put the thread through it before it goes into the thread guide. The original thread guide should put it into the correct position before it goes into the tensions, so keep it threaded through the original one, as well as the paper clip.

Give it a try and let me know what happens.

Thanks Love!!! Maxilock is the only thread use in my machines! I’ll definitely give the paper clip trick a try!!!

DeleteOMG!!! Pure amazingness! The paper clip worked like a charm! Which is crazy! I literally just got this machine out of the box! I’ve been drooling over the Juki for a while and wanted to replace my rackety old brother! Now at least I know what’s wrong! Thanks again for your help!!! You’ve saved this strike seamstress some stress!

DeleteThanks love! I use only maxi lock in my machines! I’ll definitely give the paper clip truck a try! My thoughts were exactly a defect in the tension disc! I’ll let ya know how it goes!

ReplyDeleteI have a simple brother 1034d serger And have been using it about a year and a half. As I was sewing today, it made a loud thunk noise and jammed. I cannot turn the wheel and nothing moves when i press the pedal. Motor still hums though. I ooened her up and found what looks like the needle guard loose doen under the plate. I have no idea where it goes, or how to replace it. I am pretty handy though, and would rather not pay more than the machine us worth to have it serviced. Thanks!

ReplyDeleteI don’t have access to a parts schematic for that particular serger. The question is… did it break off or fall off? Can you screw it back on? If it’s still jammed, then there’s more than just the needle guard broken off. Did you take off the needle plate? Are the loopers hitting the needle plate? Are the loopers crashing into each other? We need to figure out why it’s still jammed.

ReplyDeleteIt’s a pretty cheap machine. If it’s had a bad crash, and you get everything back to working order, the metal is soft and it’s not likely to hold the settings once you get it all re-set.

I just inherited a Bernette 334. The nylon looper gear was broken but has now been replaced and it

ReplyDeletemoves just fine. However, the timing is all out of sync and I am struggling to understand how the loopers and needles all work together (I am a visual learner and there is little out here to show me). Before I kill anymore time on this, is this machine worth fixing or probably not? (My budget for a serger was zero, so I figured it was worth a shot to try and fix it.)

Hi I have a serger 1034d and I was taking it apart to give it a good clean but as I removed the front a part came off and I love this machine but I really have no idea where this tiny piece goes

ReplyDeleteWould you like to send me a picture? I’d be glad to try to identify it. a.rose.sews@gmail

Deletewhat a fantastic post, this is so useful information. i really enjoy to read this type of post. thanks for sharing.

ReplyDeleteHi I inherited a used white superlock 504 it was pretty much seized and I have oiled the crap out of it and it works part time now.. when I move the side wheel it stops at a certain point and it's hard to get past that spot, but once I do, the machine runs like a gem.. till I stop the foot, sometimes it will start automatically and Sometimes I have to play with it to get it going again.. it tends to get "stuck" any advice where to proceed from here ?

ReplyDeleteSometimes it’s just one spot that’s got a sticky spot. Sometimes it’s a cracked gear.

DeleteThere’s a grease box on the bottom of the old White’s, where you can check for a cracked gear. So remove the bottom of the machine. Then remove the cover of the grease box. It’s a flat piece of metal toward the back of the machine, and is kinda separate from the rest of the workings. There’s usually 2 screws that need to be removed. When you get the cover off, you may need to push the grease to one side, so you can watch the gear as it goes around. If you see a crack in the gear, you know that’s what it is. You can get a replacement gear if you want to put money into it.